Elements routinely determined as weight % oxides in geological matrices are SiO2, TiO2, Al2O3, Fe2O3(total), MnO, MgO, CaO, Na2O, K2O, and P2O5. Trace elements routinely determined in geological samples at > 5 ppm ( 2 ppm for some elements) level are Ba, Sc, V, Cr, Co, Ni, Cu, Zn, Ga, Pb, Th, Rb, U, Sr, Y, Zr and Nb.

X-Ray (Fluorescence Spectrometry (XRF) )

X-ray Fluorescence Spectrometry (XRF) is one of the advanced analytical technique used for qualitative and quantitative elemental analysis (major and certain trace elements) of a variety of samples. It is widely used because of its versatile characteristics – rapid analysis, non-destructive, can analyze elements from Be (4) to U (92), higher accuracy (precision 1% - 5% relative) and sensitivity (detection limit between 0.2 and 10 ppm).

The Bruker S8 TIGER is a HighSense technology WDXRF (Wavelength Dispersive X-ray Fluorescence) spectrometer used for advanced elemental analysis. It offers an exceptional linear dynamic range enabling higher precision levels for materials research in R&D labs and industrial quality control.

Basic Principles of the XRF

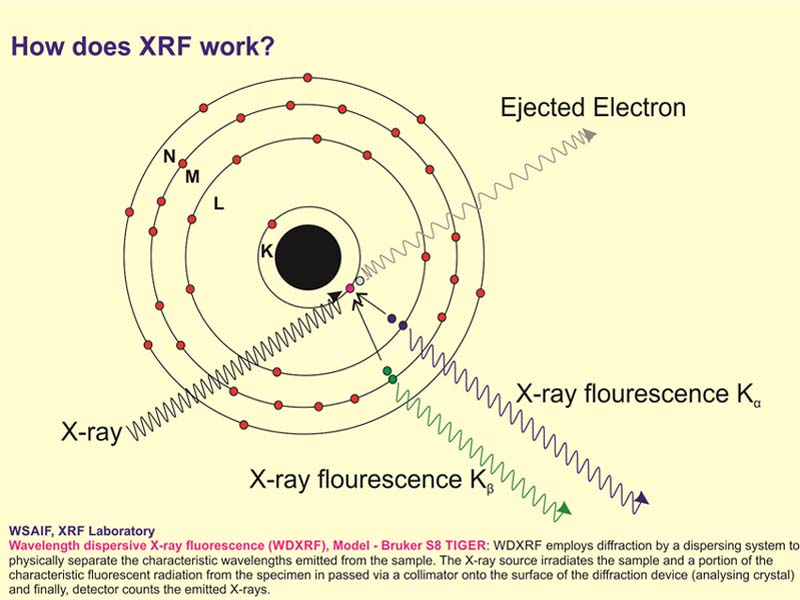

XRF works on the principle that when a flat sample is bombarded by an X-ray beam, it excites the sample and generates X-ray fluorescence. The radiation emerging from the sample includes the characteristic X-ray peaks of major and trace elements present in the sample.

Dispersion of these secondary X-ray into a spectrum, usually by X-ray diffraction, allows identification of these elements present in the sample. The height of each characteristic X-ray peaks relates to the concentration of the corresponding element in the sample, allowing quantitative analysis of the sample for most elements. The Solid samples are analysed in the form of pressed powder pellets or homogenised glass fused beeds.

Routine Analysis

-

-

The required sample size is ~200 mesh, preferably in the form of sample powder (~20 gm).

-

In order to create the pellets, the powdered sample is mixed with 4-5 drops of polyvinyl alcohol manually. The mixture is then compressed using an automatic hydraulic press (40 tons) with variable load pressure, resulting in disc-shaped pellets (35 mm X 3 mm).

-

Loss on ignition (LOI) also calculated using the formula: L.O.I. (Wt %) = {(n2 - n3)/ n1}*100 Where, n1: weight of the sample n2: weight of crucible + sample (before heat) n3: weight of crucible + sample (after heat at 950ºC for 1h).